Wastewater Quality Monitoring 24/7 At Pepsico Quang Nam

Increasing safety in a wastewater treatment process

Suntory PepsiCo Vietnam Beverage is one of the top national beverage leaders, the success and popularity of their top ten brands have prompted them to set the goal of bringing in $1 billion in annual retail sales in 2018. Their full attention is focused on the soft drinks, they are not enough experience for building a comprehensive solution to follow all requirements of environmental protection. Even though the basic design of wastewater treatment section is principally similar, but the process systems in plants are different while the precondition for efficient measurement is the knowledge about the process characteristics of the individual plant sections.

For this reason, PepsiCo relies on NK Engineering and its years of know-how in industrial measuring instruments to install an automatic wastewater quality monitoring station as The Ministry of Natural Resources and Environment requested.

Our solution

The overall control system of Online Monitoring offered by NK Engineering includes 6 parameters: pH, COD, TSS, Chlorine residual, Colour, and Flow rate will be transferred and online 24/7 with real-time via Web server.

All sensors are featured IP68 protection and integrated Endress+Hauser cutting-edge technology – Memosens. These analysis sensors will be automatically cleaned by compressor air. COD sensor, in particular, will be washed with a Hydrochloric acid 3.5÷5% to ensure good performance in the wastewater environment of PepsiCo.

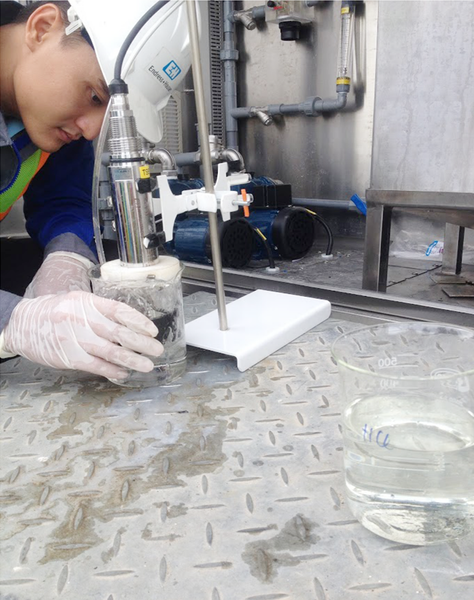

On-site calibration TSS sensor

All data will be recorded every 1 minute in color graphics display for each monitoring parameter by data logger Ecograph T RSG35 and backup in daily, weekly, monthly and yearly and also export to excel file easily for document purpose. All monitoring parameters will be connected to the GSM/GPRS wireless transmitter for continuous data transfer to the data acquisition.

Alarms issued automatically if limit values are not reached or are exceeded.

Data logger Ecograph T RSG35

Customer benefits

– Process reliability and control Thanks to continuously measured values and signal validation, this system guarantees stable plant operation and reliable plant discharge. Even after installation, plant personnel has full control of the process at all times.

– Easy maintenance, short downtimes High plant availability, easy calibration and user-friendly maintenance thank to Memosens technology.

Whether you need to update your instrumentation to comply with legal requirements, improve efficiency or streamline your processes, please contact us at sales@nkengineering.com.vn for more assistance.