HEARTBEAT TECHNOLOGY IN THE FOOD INDUSTRY

Proline 100/300/500 hygienic instruments

Challenges in the food industry

Food and beverage manufacturers operate in accordance with strict guidelines. Food authorities require that manufacturing processes including measuring technology undergo a validation process. Each type of measuring equipment must be calibrated or verified regularly in accordance with ISO 9001:2008. Here the operator must comply with the rules of metrologically traceable verification in order to avoid delays and costly adjustments during the recertification process.

Requirements for an optimized solution It would be ideal if devices could be verified without interrupting the process so as to reduce risk and save both time and money.

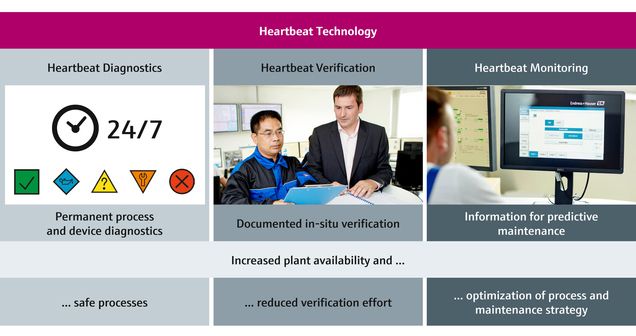

Our solution Thanks to Endress+Hauser Heartbeat Technology, measuring points are verified in situ and without any interruption to measurements or processes. In addition, verifications no longer need to be performed on-site and instead can be carried out easily from the comfort of the control room. The associated asset management software generates and maintains PDF files for documentation purposes.

Benefits

– With Heartbeat Technology, the operator maintains complete flexibility when it comes to scheduling a measuring point inspection, as there is little effort involved and it can be performed while the plant is in operation. The time saved from when a connection is established to when the documentation is completed is generally in the region of 80% compared with verifications using external test and inspection equipment (such as Filedcheck).

– Extended calibration cycles result in additional savings in maintenance costs and increased plant availability: calibration is required only every two to three years instead of annually.